Magnet-free axle drive EESM

Schaeffler is advancing electric vehicle technology with its new magnet-free externally excited synchronous machine (EESM) rotor, an innovative option for its EMR4 (Electronic Motor Reducer, 4th generation) axle drive platform. This development addresses several key challenges associated with Permanent Magnet Synchronous Machines (PSMs), which are currently the standard in EVs.

Key advantages of Schaeffler's EESM rotor

Sustainability and cost stability

The EESM rotor eliminates the need for rare earth materials like Neodymium (Nd) and Praseodymium (Pr), which are subject to volatile pricing and environmental concerns associated with their production. This provides a more stable price and reliable delivery compared to PSMs.

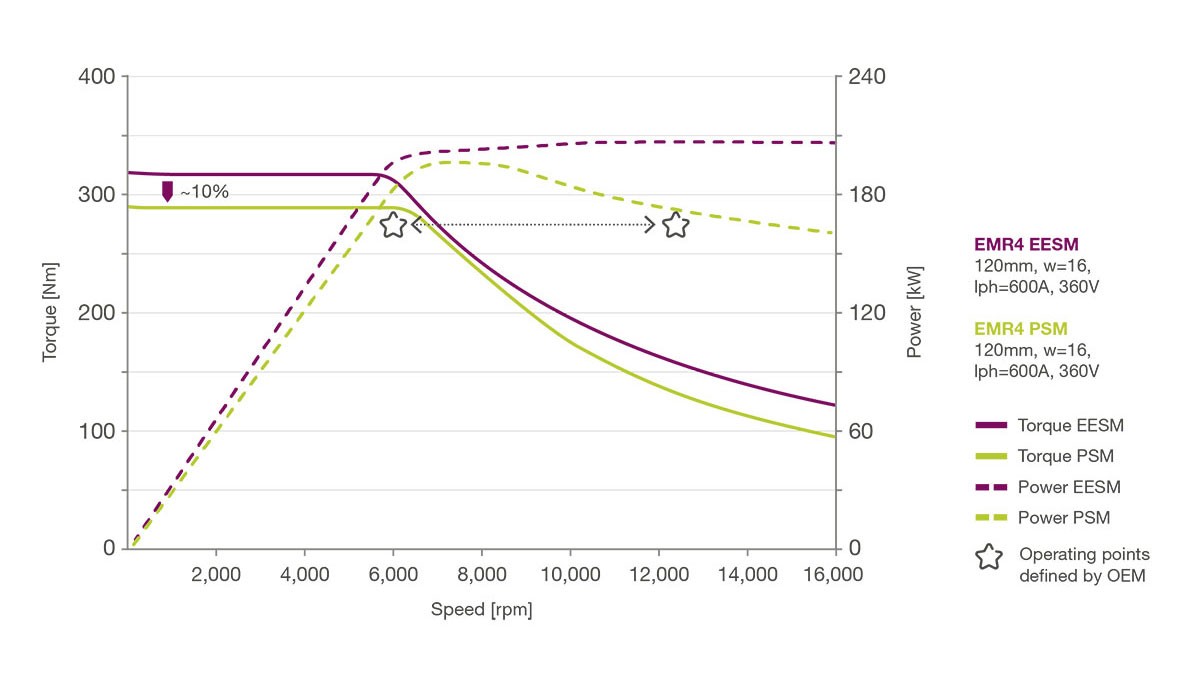

Enhanced performance at high speeds

Unlike PSMs, which are optimized for lower speeds and torques, the EESM can maintain an almost constant power range even at high speeds, benefiting long-distance driving and trailer operation. The EESM can achieve higher torque at high speeds than PSMs.

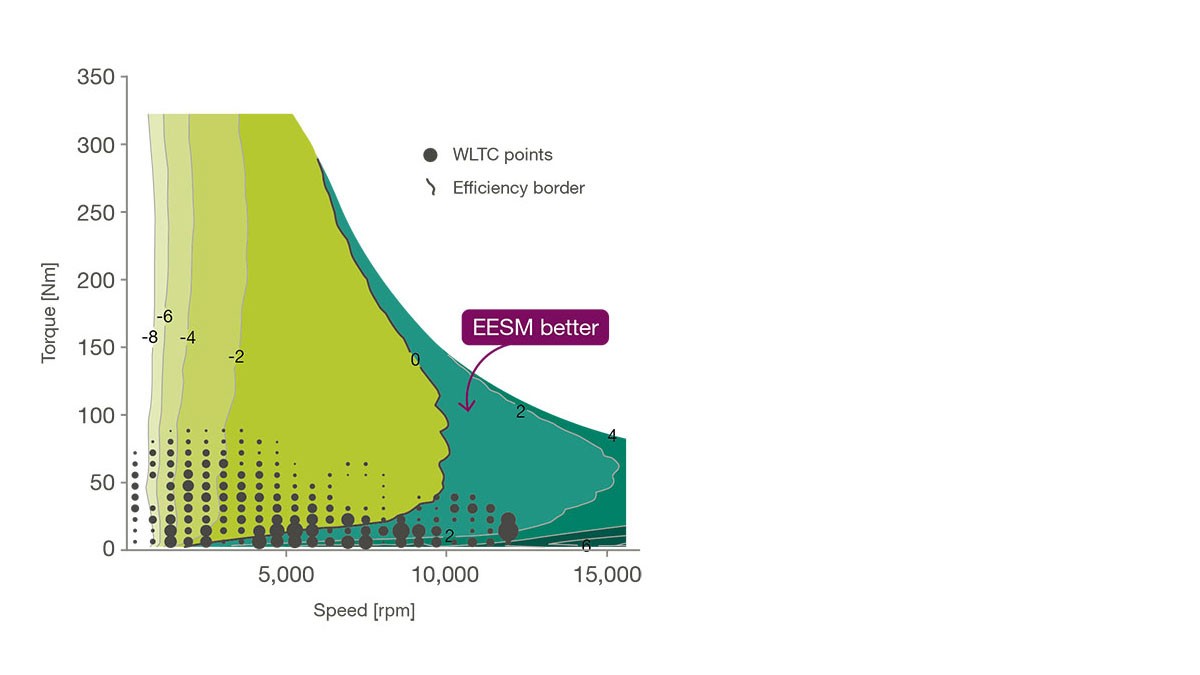

Improved efficiency in specific driving profiles

The EESM demonstrates greater efficiency in the medium speed range at very low loads and torques (under 15 Nm), and increasingly at higher speeds and torques due to reduced iron losses in the stator. It also produces fewer harmonic losses compared to PSMs, contributing to overall better performance in driving profiles with a higher proportion of country roads or freeways.

Cost-effectiveness at higher power outputs

While PSMs have advantages in power density, installation space, achieved cost optimization and efficiency, the EESM is expected to reach price parity with PSMs around 150 kW and become more cost-effective at higher power outputs, with a potential for 8-12% cost reduction. Depending on raw material costs, the price parity between EESM and PSM is in a power range of around 120 kW to 150 kW.

Proven and simplified energy transmission

Schaeffler utilizes an optimized, maintenance-free brush system for transmitting excitation current to the rotor, a solution proven over the lifetime of previous EMR generations (300,000 km/15 years). This system offers significant cost and complexity reductions compared to inductive transmission systems.

"Plug-and-play" option

The EESM rotor is a "plug-and-play" option within the EMR4 platform, allowing vehicle manufacturers flexibility to choose between magnet-free and PSM units based on market and vehicle type requirements. Schaeffler anticipates that EESMs could account for approximately 8% of the electric drive market by 2030, with potential for up to 40% if geopolitical factors impact rare earth supply chains.

Contact

Do you have any questions about Schaeffler's magnet-free axle drive, or would you like to know more about this product? Then contact us.